Holdbacks, Sprags and Clutches

BTS maintain stocks of a number of Bibby Turboflex, Marland and Stieber backstops, sprags and clutches.

BTS maintain stocks of a number of Bibby Turboflex, Marland and Stieber backstops, sprags and clutches.

uniformly high torque capacity and have good load carrying ability. They are normally anchored with a torque arm which must not be constrained in anyway.

Literature:

Marland BC

Marland Holdback service manual

drive fully loaded conveyors, kilns or bucket elevators to stop them running back for any reason.

These holdbacks use the centrifugal pawl system.

There are 3 types of high speed holdbacks:

Advantages include :

Literature:

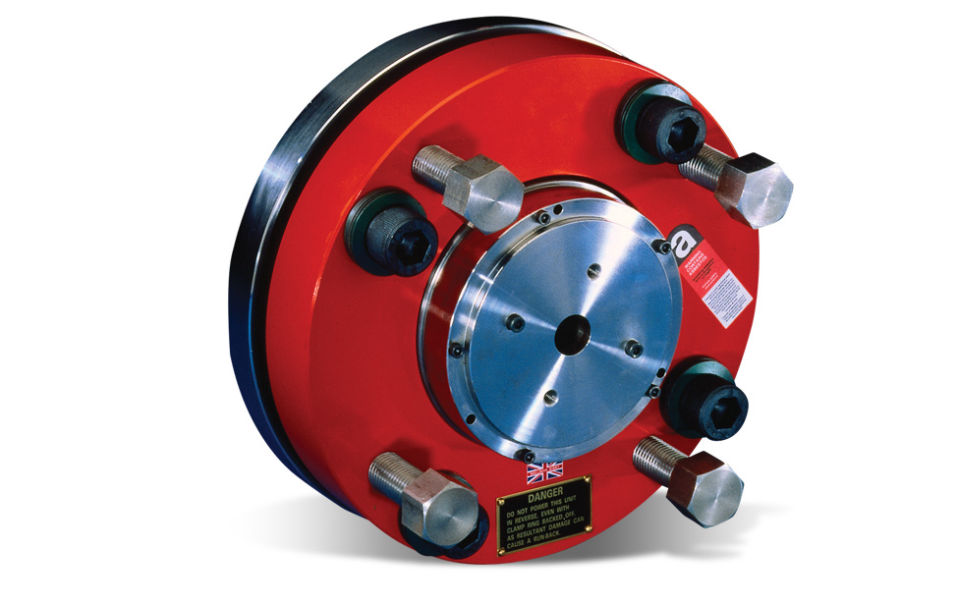

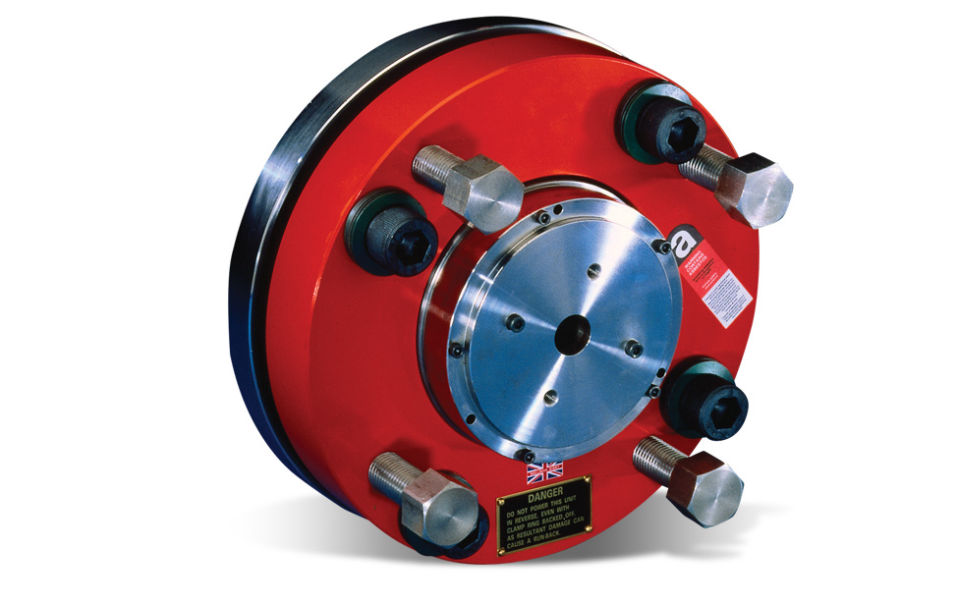

Bibby Holdbacks

This website was designed with Mobirise